Material cutting

We cut bar stock up to a diameter of 250 mm; larger blanks are ordered pre-cut to size. Our equipment includes 3 conventional saws and 1 CNC saw. Difficult-to-machine materials – such as hardened piston rods, HSS steels, etc. – are cut using wire EDM.

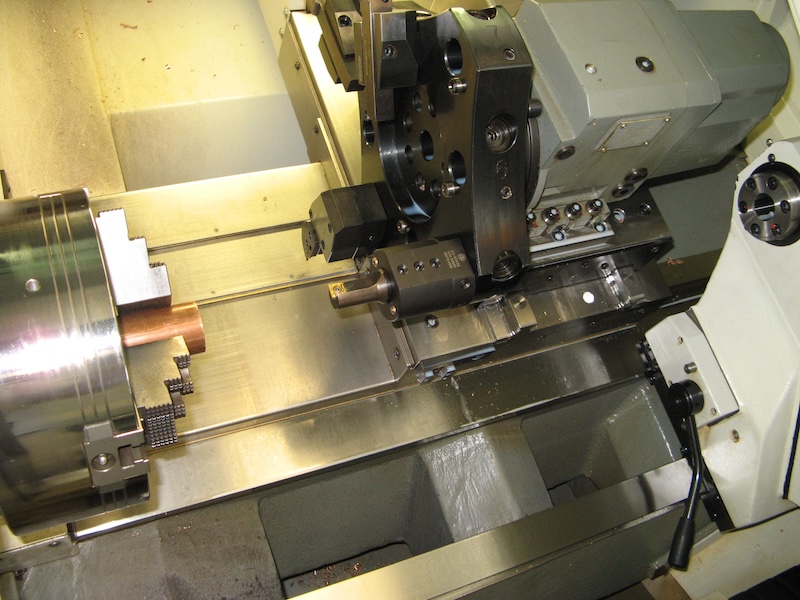

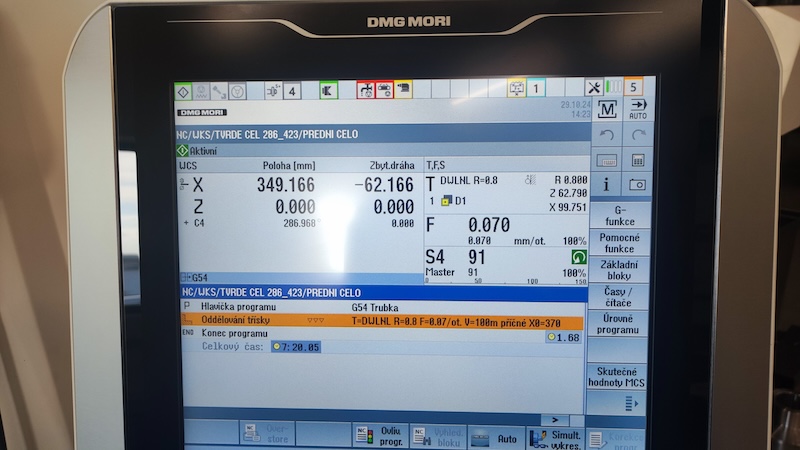

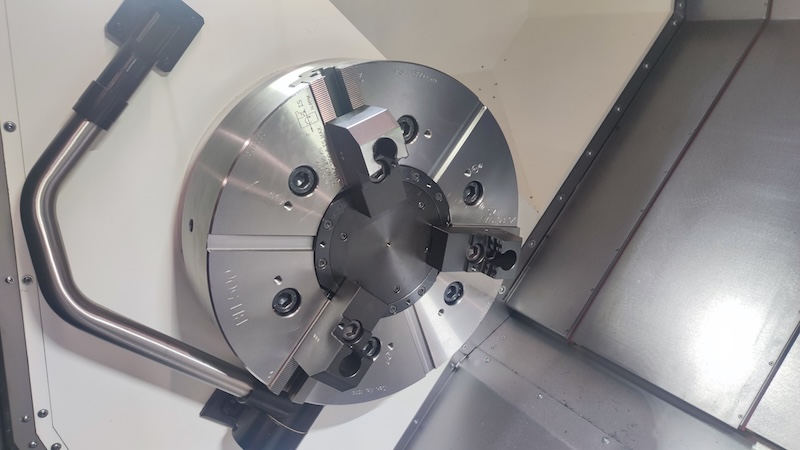

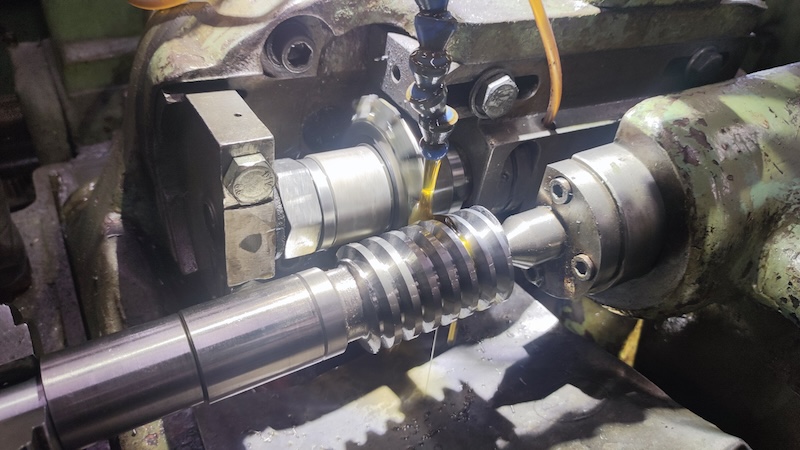

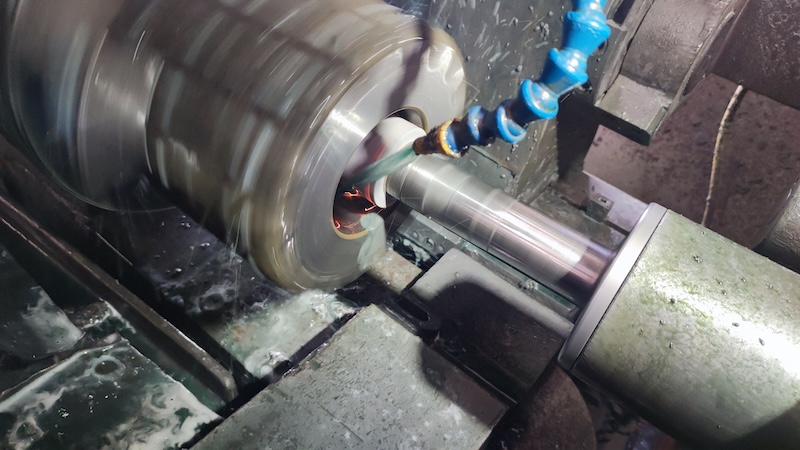

Turning

For the preparation of gear blanks we use 2 conventional lathes with digital readout and manual chucks, and 3 CNC lathes with hydraulic chucks. All CNC machines are equipped with high-pressure pumps for internal cooling. We are self-sufficient in both conventional and CNC turning up to a diameter of 500 mm, which corresponds to the maximum gear diameter with ground teeth that we are capable of manufacturing.

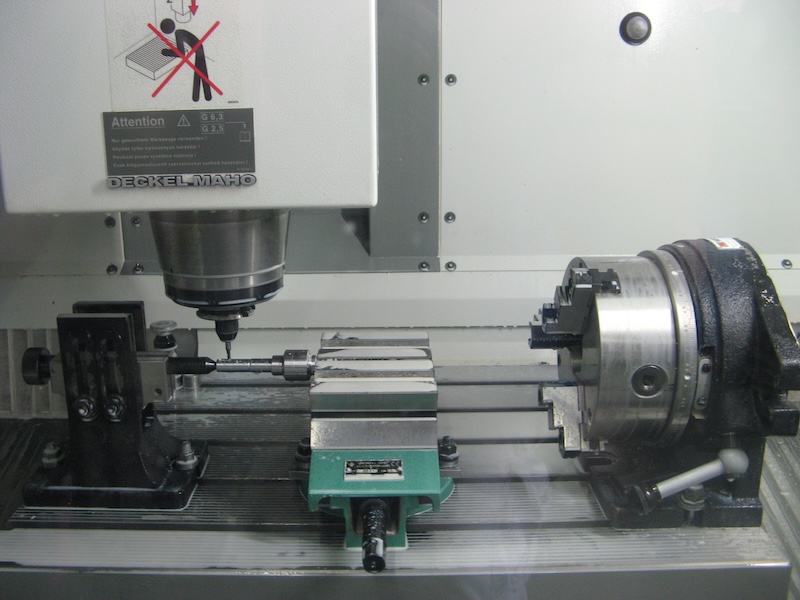

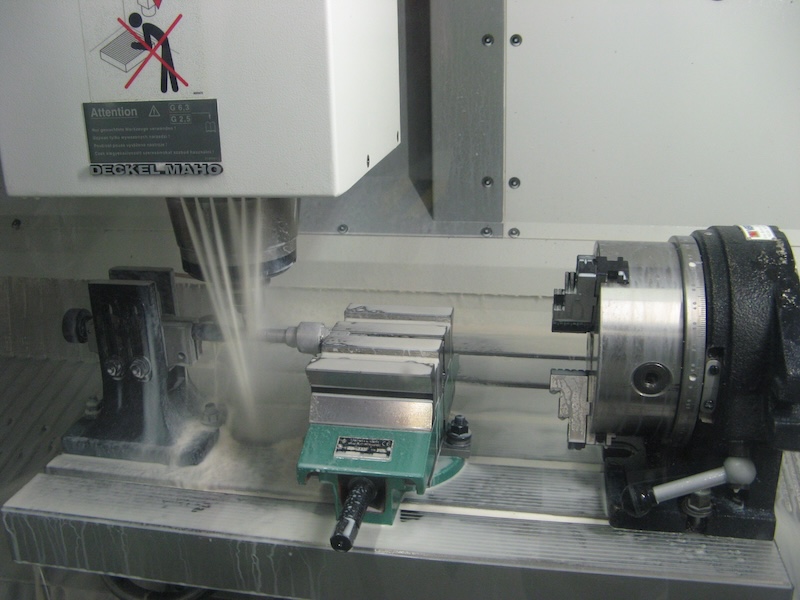

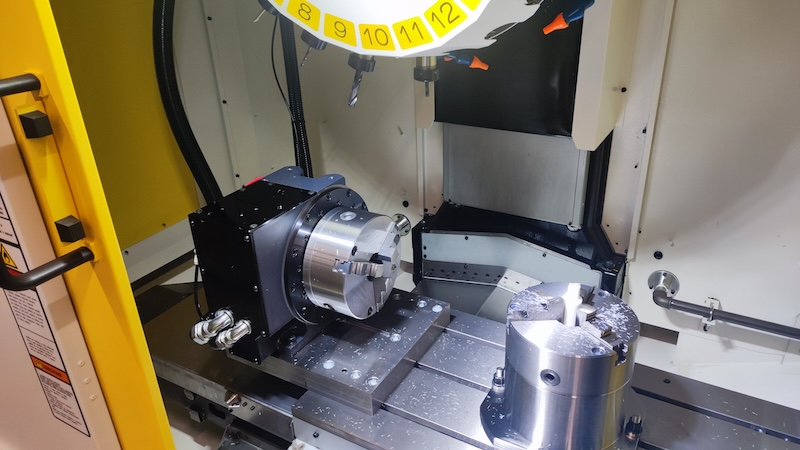

Milling

For drilling, tapping, producing keyways, face couplings, etc., we use 1 conventional milling machine and 2 CNC machines – one 3-axis and one 4-axis with a rotary table driven by a built-in servomotor. Both CNC machines are equipped with tool and workpiece probes; one of them also features a high-pressure pump for internal cooling.

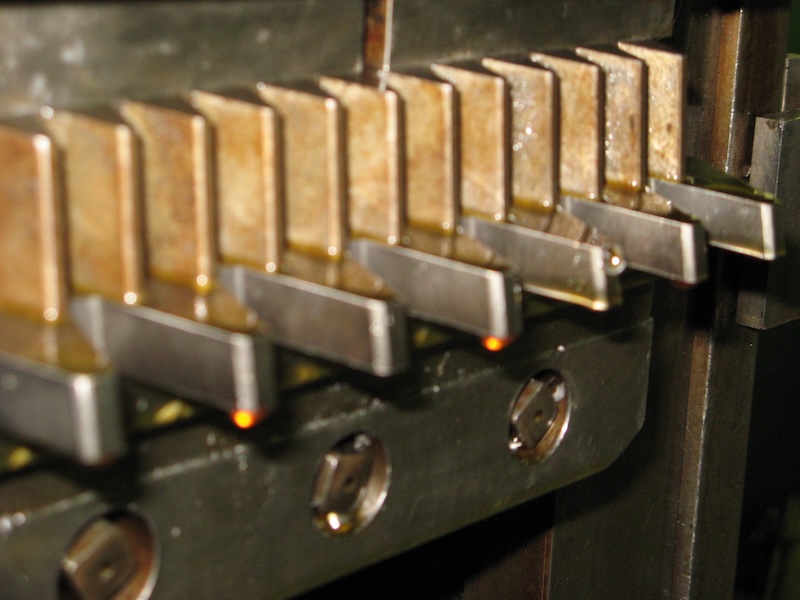

Shaping

For internal keyways we use 2 conventional slotting machines and 1 CNC machine with a table driven by a servomotor, allowing precise indexing. The largest machine has a table diameter of 800 mm and a stroke of up to 400 mm. The slotting machines are also used for producing straight-sided splines, and in cooperation with wire EDM machines, for replacements of involute splines in both metric and inch series.

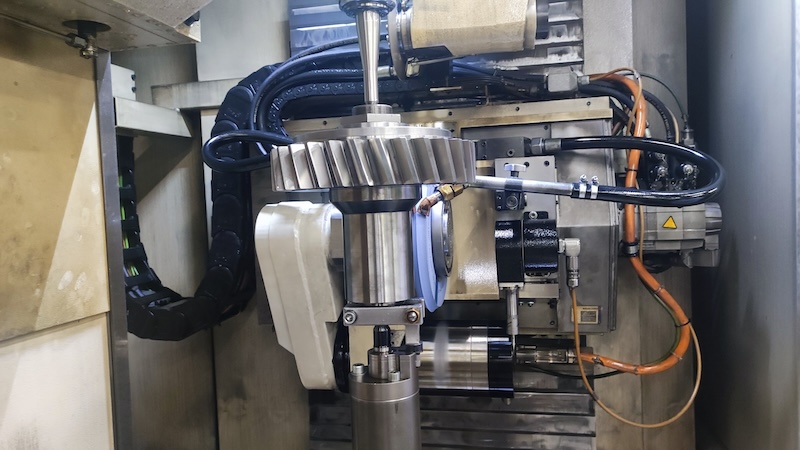

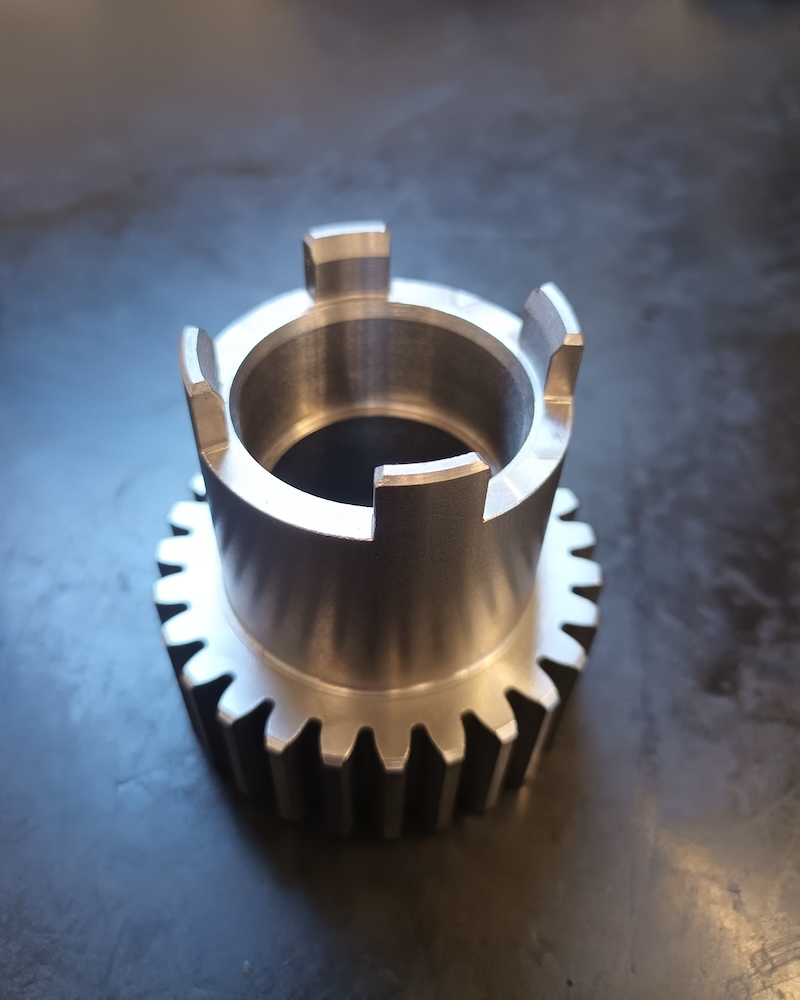

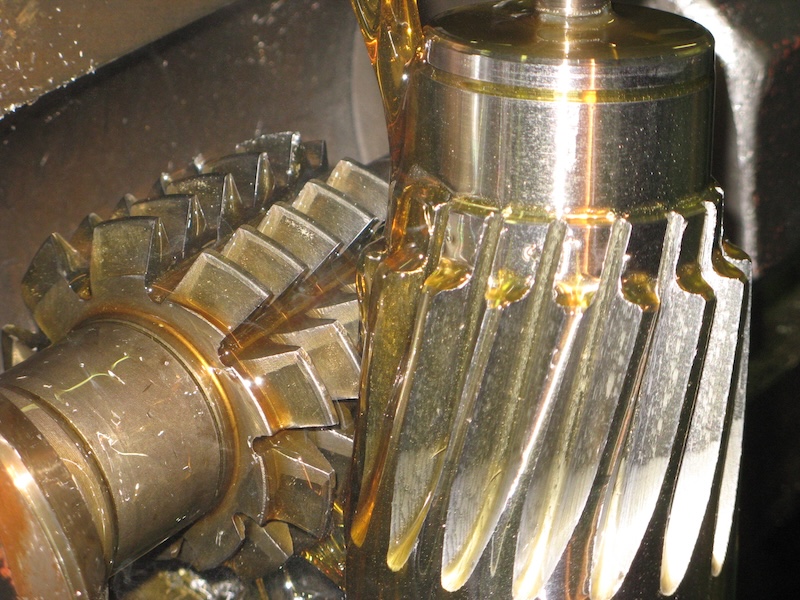

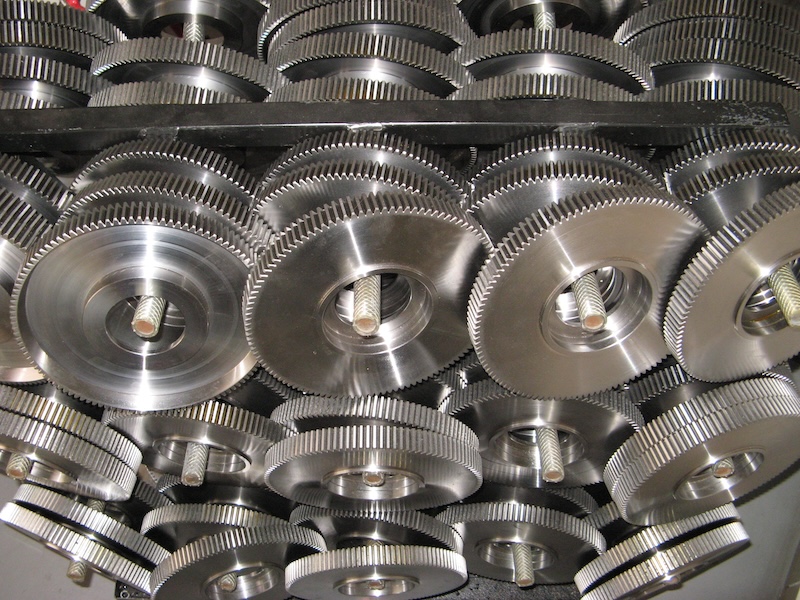

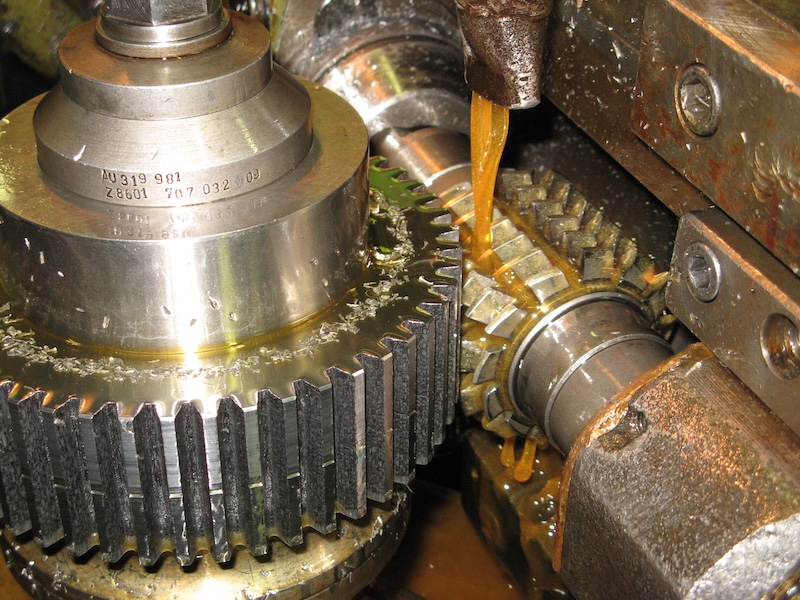

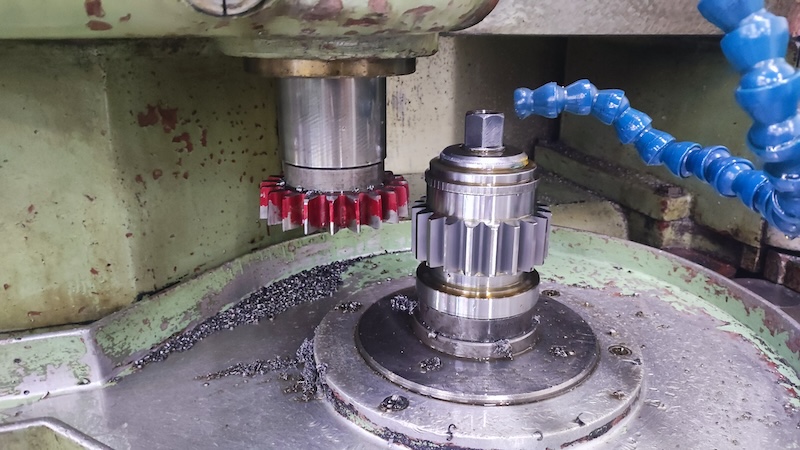

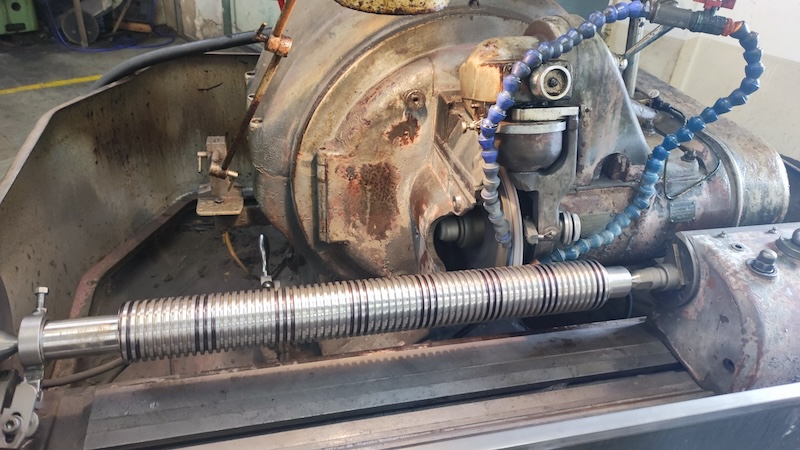

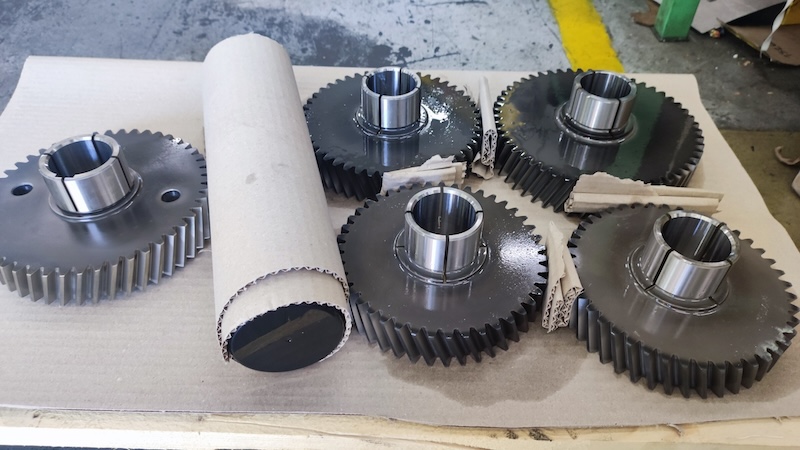

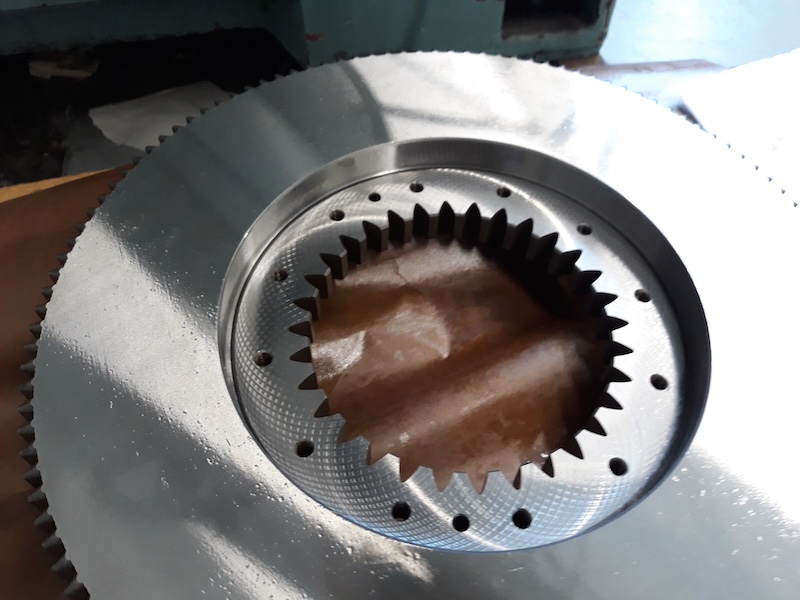

Gear hobbing

At Bondy s.r.o., the production of gearing involves more than 40 special-purpose machines and devices, in addition to 5 universal machines. The largest group is represented by gear hobbing machines. Gears can be hobbed to final dimensions or with stock allowance for grinding. Pre-grinding gearing is produced using undercutting hobs according to ČSN standards or non-undercutting hobs according to DIN standards. For selected modules we have hobbing machines with chamfering capability, while CNC machines are able to produce certain modifications (e.g. barrel-shaped teeth).

In addition to spur and helical gears, a wide range of other products is manufactured on hobbing machines – sprockets, involute and straight-sided splines, worm wheels, screw gears, etc. Many hobbing machines are equipped with special accessories such as tangential heads or extended hob spindle bearings.We also hob worm threads on horizontal milling machines. Among all Bondy s.r.o. workshops, the gear cutting shop is the best equipped in terms of capacity for external cooperation – approximately 50% of our production consists of cutting gearing on customer-supplied blanks.

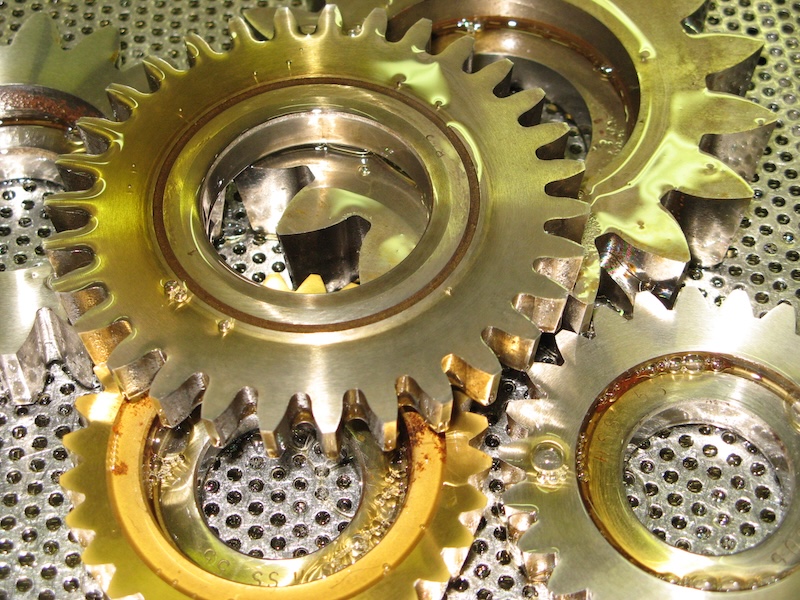

Gear shaping

Although the Maag method (rack-type shaping) is in decline, the Fellows method (gear-type cutter or pinion cutter) still holds a strong position among applied processes. Certain components – such as gears or even gear shafts – do not allow a hob to exit the mesh; in such cases, gear shaping is the preferred solution. For small internal gears or splines, the only alternative to pinion-type shaping would be broaching, which is not economically viable in single-piece or small-batch production.

Hobbing by shaping remains a method that is difficult to replace. In addition to external and internal spur gears and splines, gear shaping also enables the production of sprocket gearing as an alternative to gear hobbing.

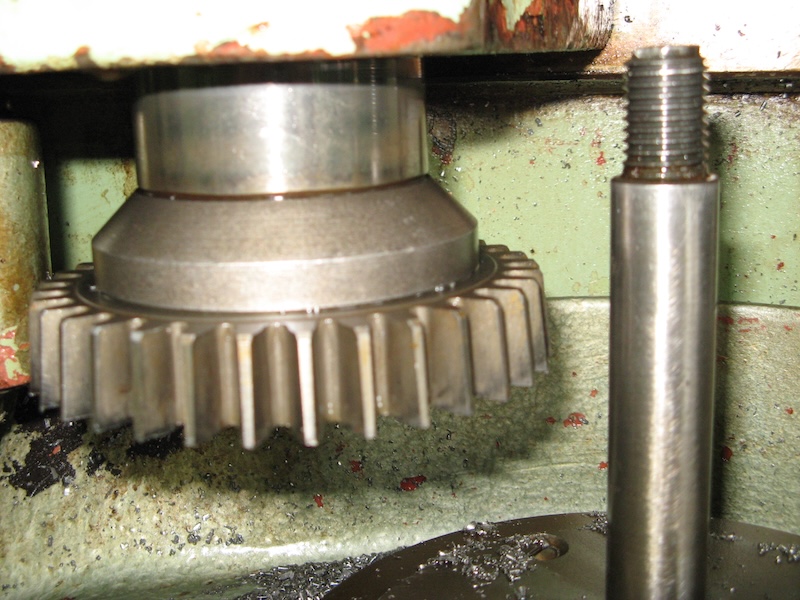

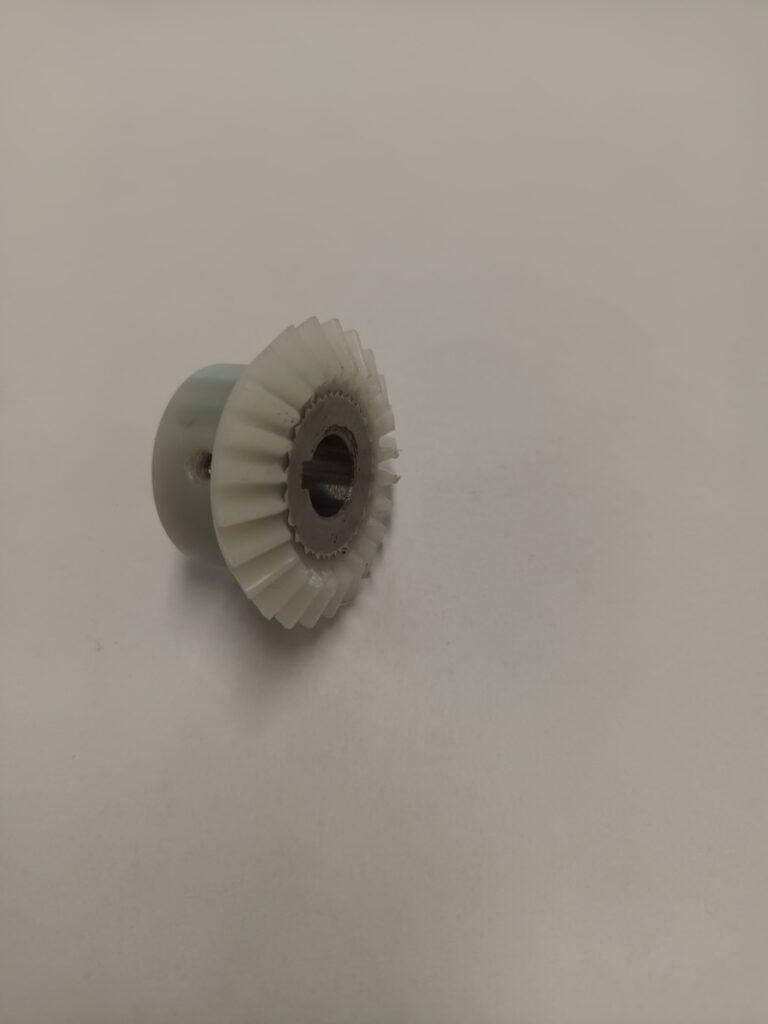

Straight bevel gears

Straight bevel gears are the most commonly manufactured type of bevel gearing. The smallest pinion we have produced had a module of 0.5 and a diameter of 10 mm, while our largest machine can handle up to module 18 and a diameter of 750 mm. In addition to standard production, we occasionally replace non-manufacturable spiral bevel gears with straight bevel gears. Thanks to many years of experience, we also offer various special solutions beyond the primary capabilities of these machines – for example, bevel gears with shaft angles other than 90°, or pinions with very small values of root cone angle.

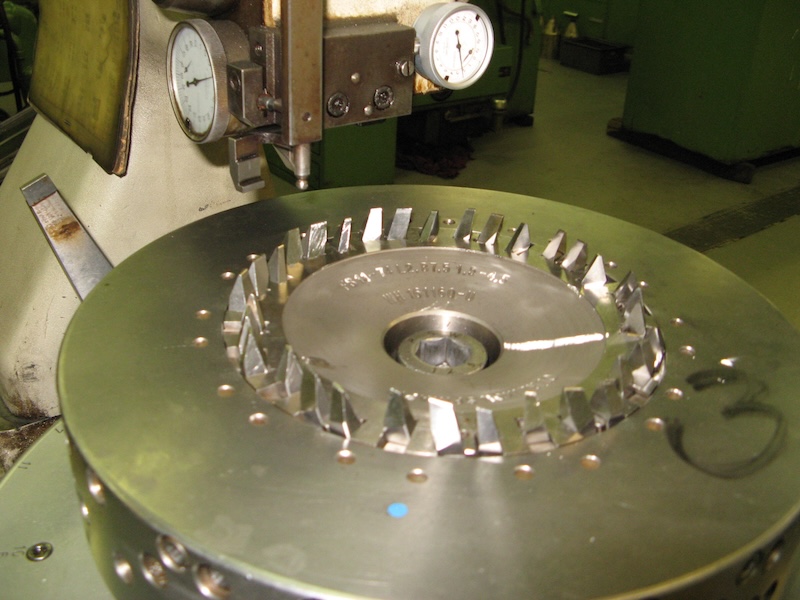

Spiral bevel gears

Among spiral bevel gears, we produce Klingelnberg-toothed gears using spiral bevel hobbing machines, and Oerlikon cyclo-palloid gearing using cutter heads. Inspection of both types has been unified on an Oerlikon motorized roll tester, which, thanks to the built-in brake, provides a more accurate representation of the gear set’s real operating behavior. In Oerlikon technology, due to the high cost of tooling preparation for new production, we offer customers already tooled gear sets, for which the preparation costs have been covered. With minor design modifications, these can be adapted and integrated into their applications.

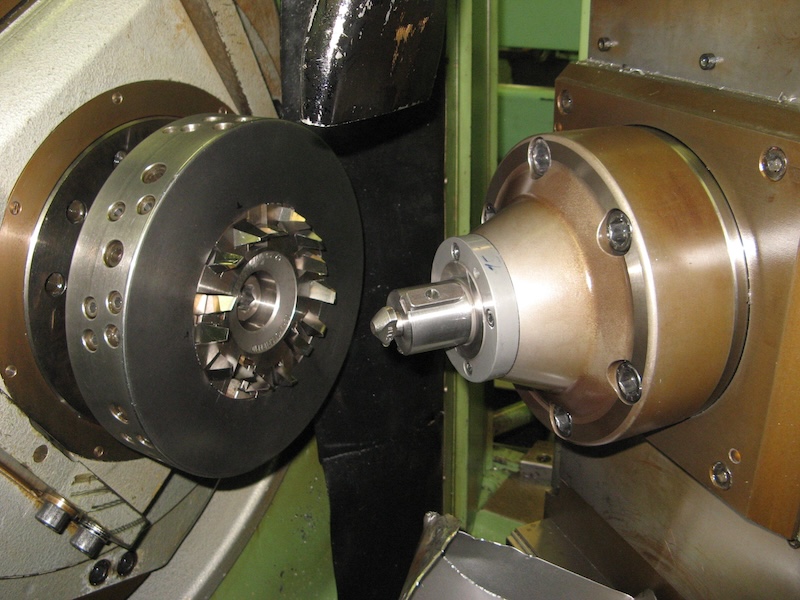

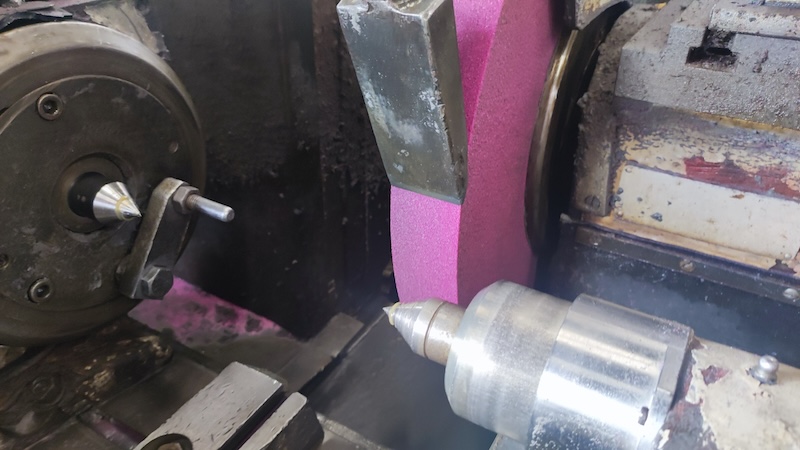

Grinding

Without high-quality bases, it is not possible to manufacture precise gearing. Bondy, s.r.o. operates a fully equipped grinding shop. Our internal grinders enable simultaneous grinding of the bore and the face of gears – either with the wheel face or with a swiveling arm. A surface grinder then ensures the parallelism of both faces. Cylindrical grinding is carried out on center grinders, with the possibility of grinding faces using the wheel sides. We also perform external and internal taper grinding, external trapezoidal thread grinding, refurbishment of gear pump covers, and similar work. More complex workpieces are ground on toolroom grinders.

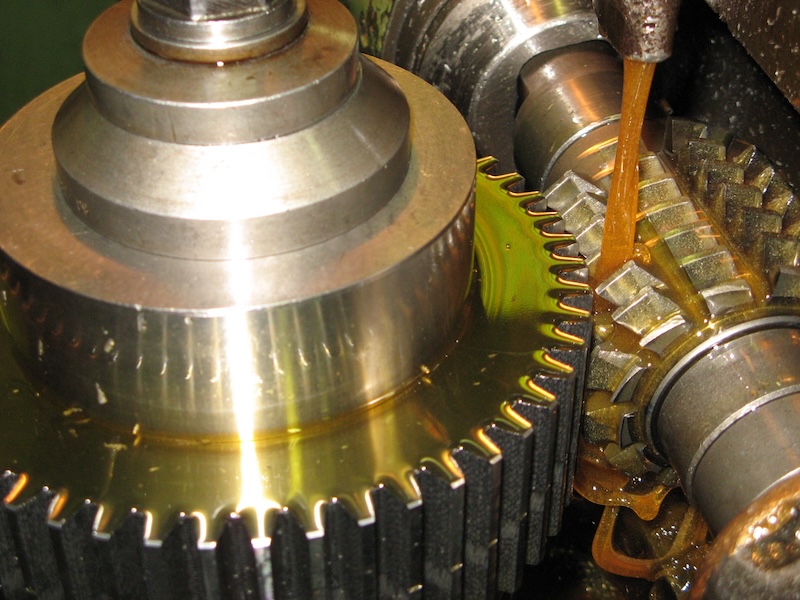

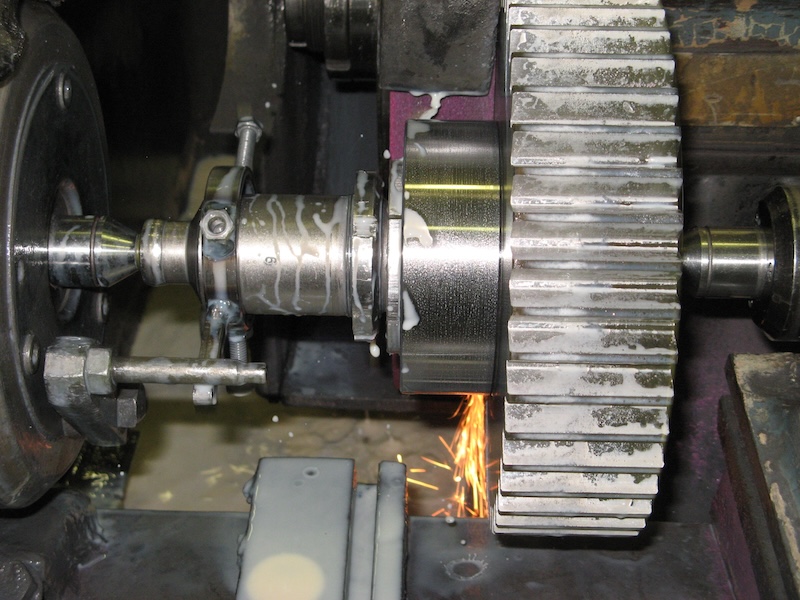

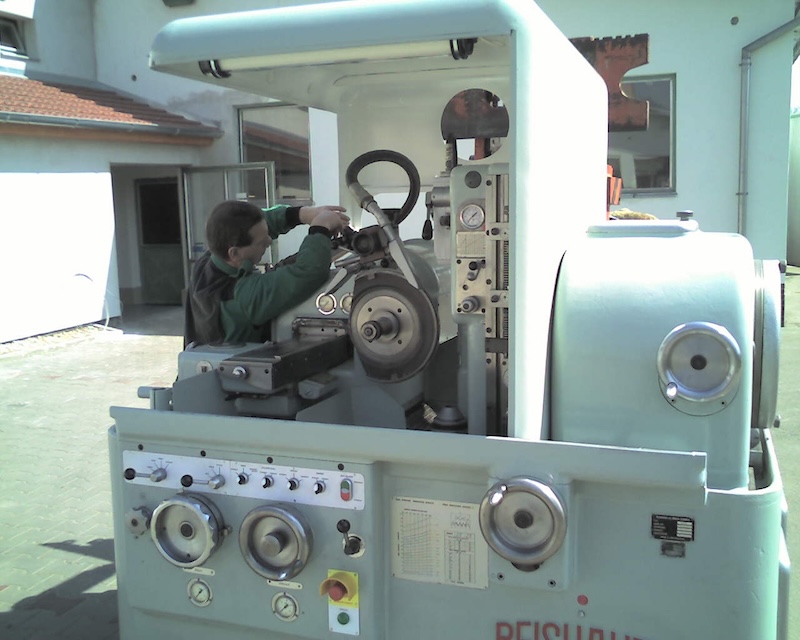

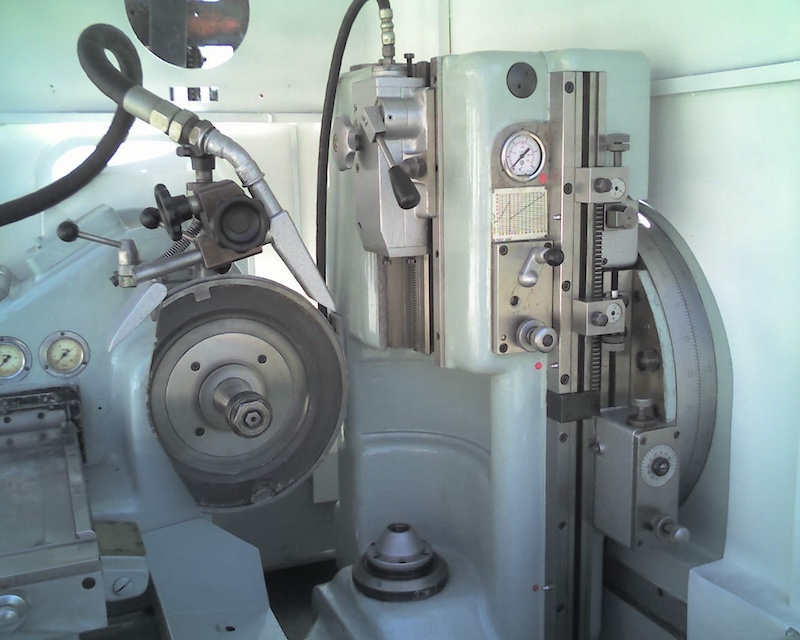

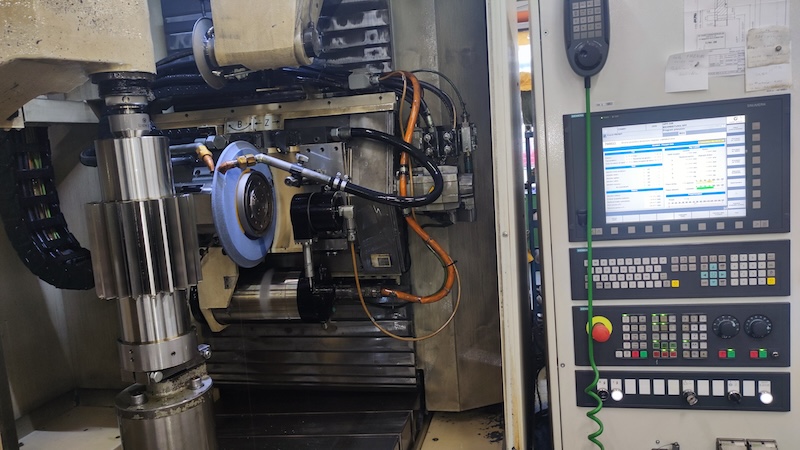

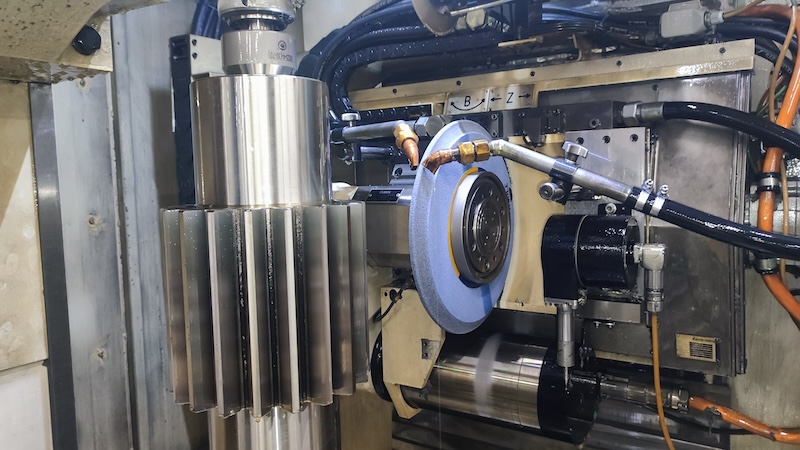

Gear grinding

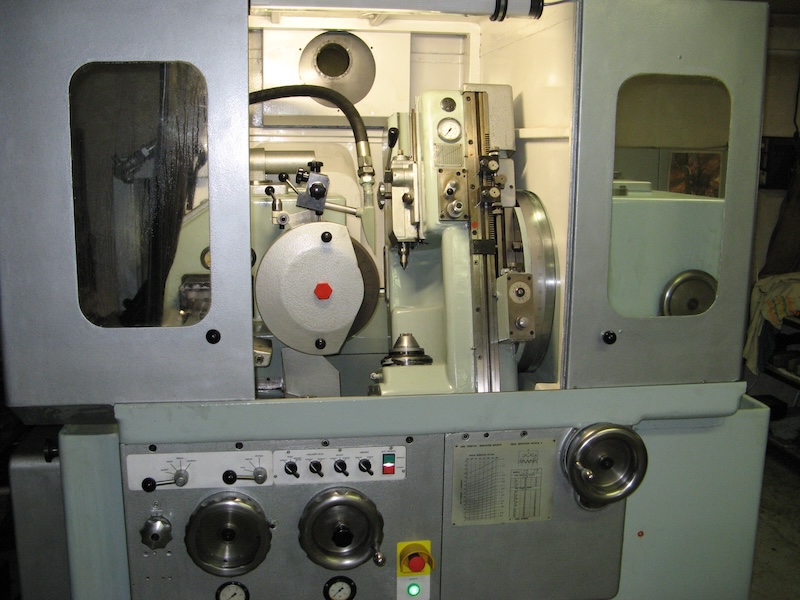

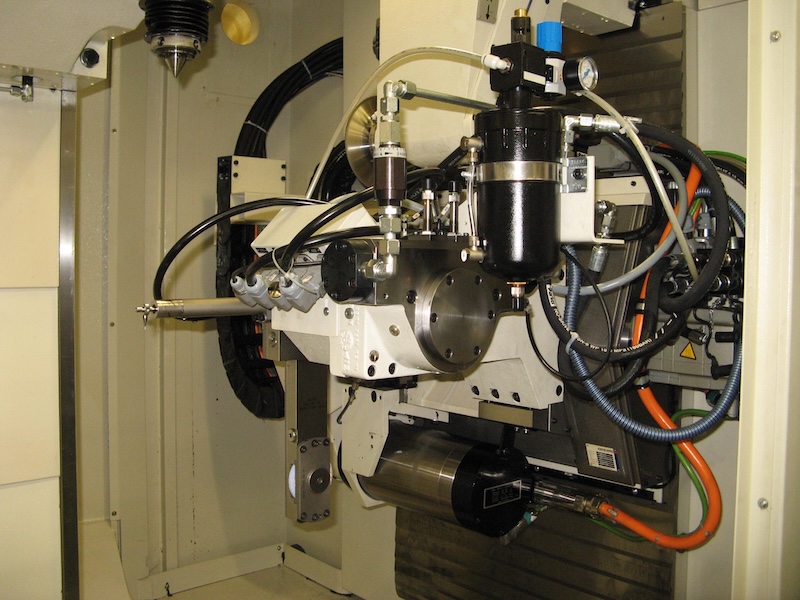

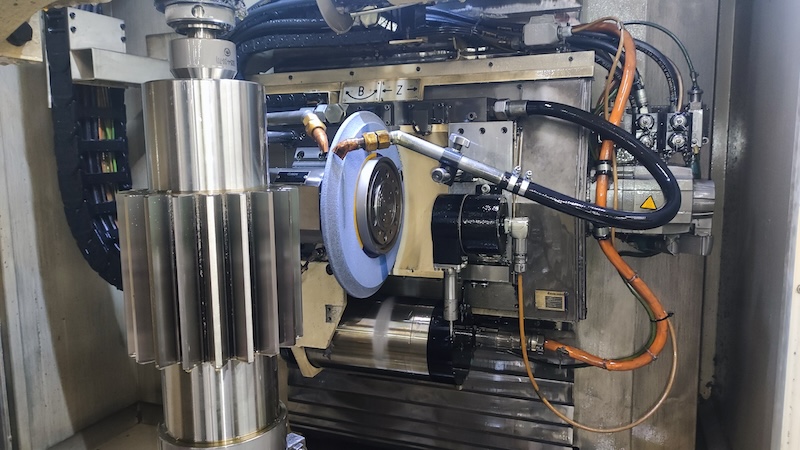

Gear grinding has a long-standing tradition at Bondy, s.r.o. Even during times of severe shortage and limited availability of grinding machines, we started with general overhauls of Čelákovice OBP grinders. Some of these were sold to customers both in the Czech Republic and abroad, while others served, or still continue to serve, our own production needs. We also operated several conventional profile grinders. The experience gained over many years of work on conventional machines has been transferred to the latest CNC equipment.

Today, we operate OBP 32 and Reishauer AZA generating gear grinders, and for the most demanding applications we use a Kapp-Niles profile grinder. Thanks to an integrated measuring probe, we can verify directly on the machine whether the part being finished meets the required specifications. The probe also enables highly accurate centering on multiple teeth (or on all of them), allowing us to eliminate manufacturing inaccuracies, deformations after heat treatment, and similar issues. We frequently salvage components that other companies are unable to process.We can provide references from machine tool manufacturers who insist that gears intended for their gearboxes are ground and certified exclusively by us. Our grinding capabilities include external and internal spur gears, straight-sided and involute splines, non-standard gears, ultra-precise gears, worm threads, and many other elements.

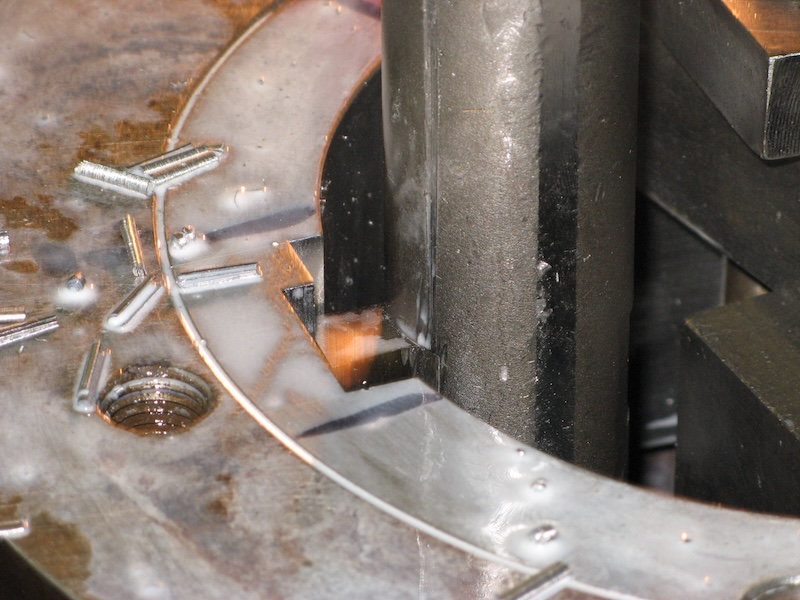

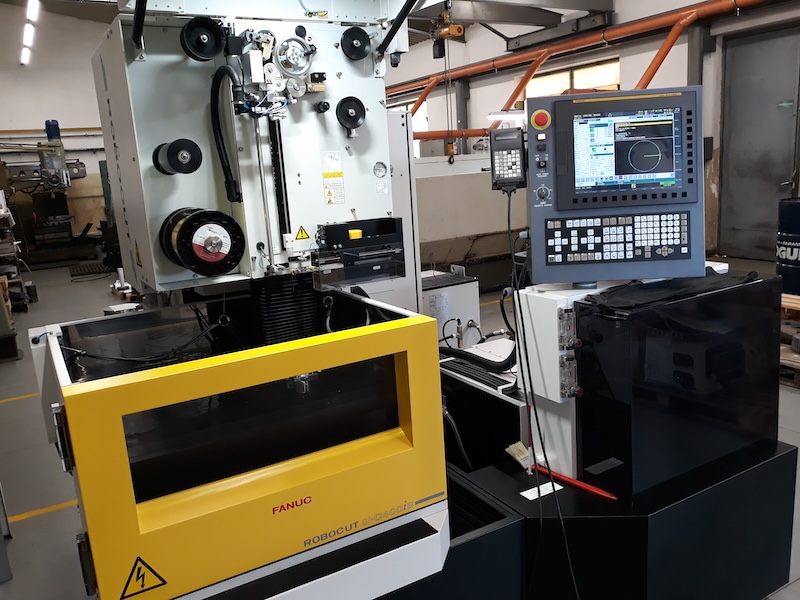

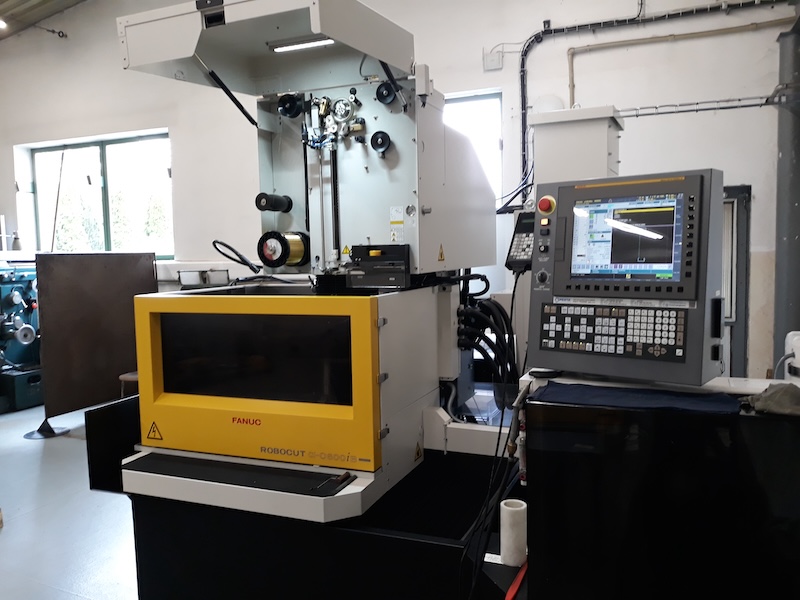

Electrical Discharge Machining (EDM)

Electrical discharge cutting is a technology that we have acquired relatively recently. The frequent need for outsourcing this process led us to establish our own in-house EDM department. We operate two Fanuc wire-cut EDM machines with cutting heights of up to 400 mm and external programming capabilities. These machines are indispensable for finishing narrow and deep holes, keyways, or, conversely, oversized openings that are too large for standard grinders. They enable the production of segments, racks, and other non-rotational gearing components. In combination with specialized software and our gear manufacturing expertise, they also produce internal and external gears and splines, custom chain sprockets, HTD pulleys, and much more.

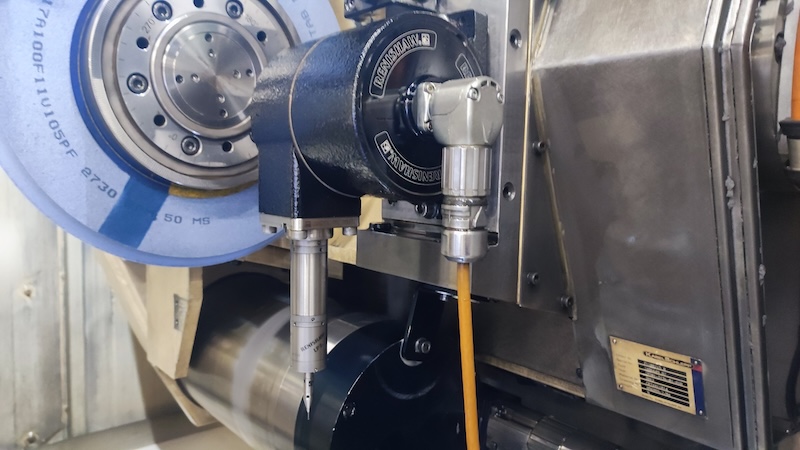

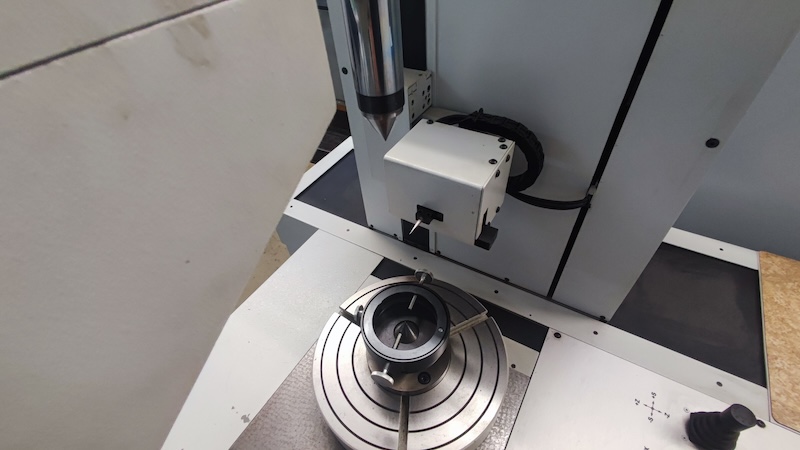

Inspection & Quality Control

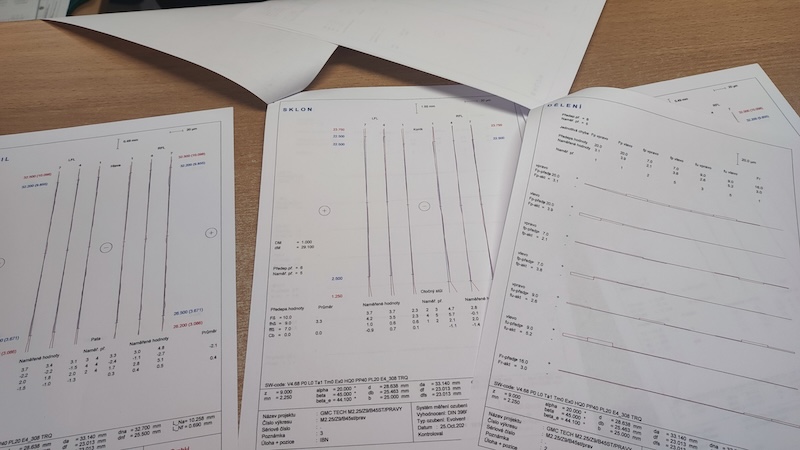

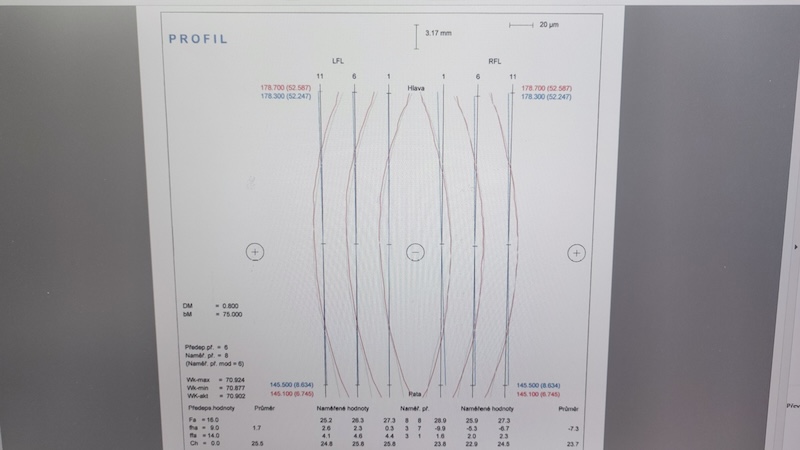

The Quality Control Department at Bondy, s.r.o. focuses primarily on gear measurement. CNC inspection is performed directly on the profile grinder using an integrated Renishaw probe, ensuring that no defective part can be unclamped without operator awareness. Independent verification is carried out with the internationally recognized Klingelnberg test. The consistency between both measurement systems is continuously monitored using calibration master gears supplied by the equipment manufacturers.

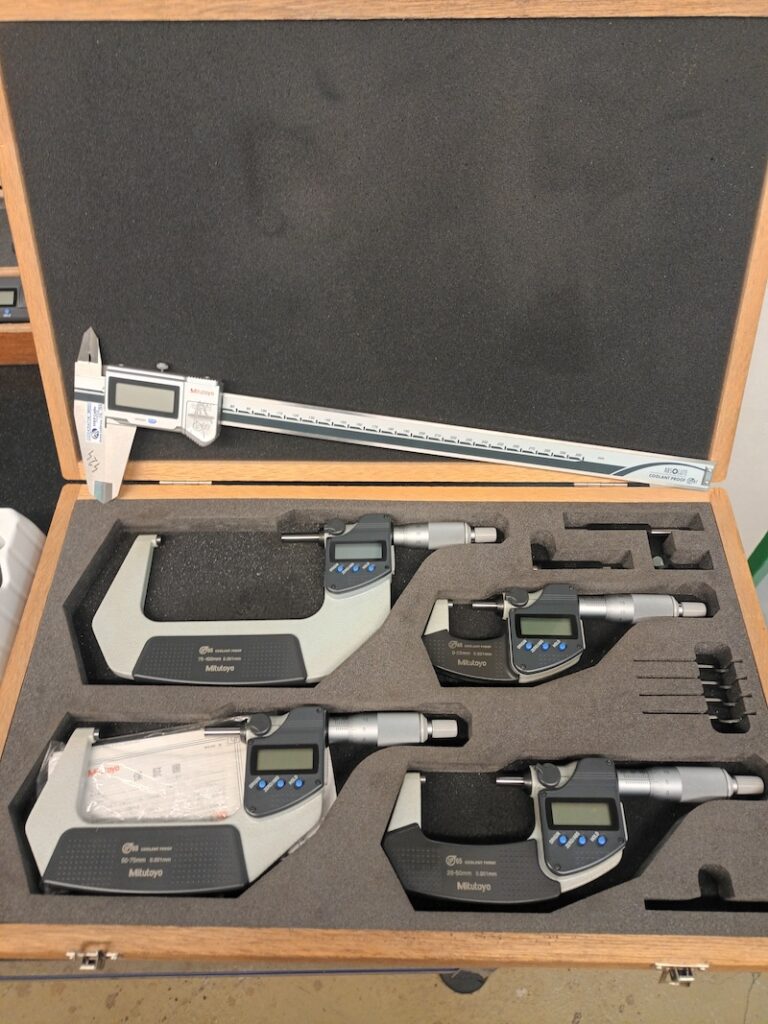

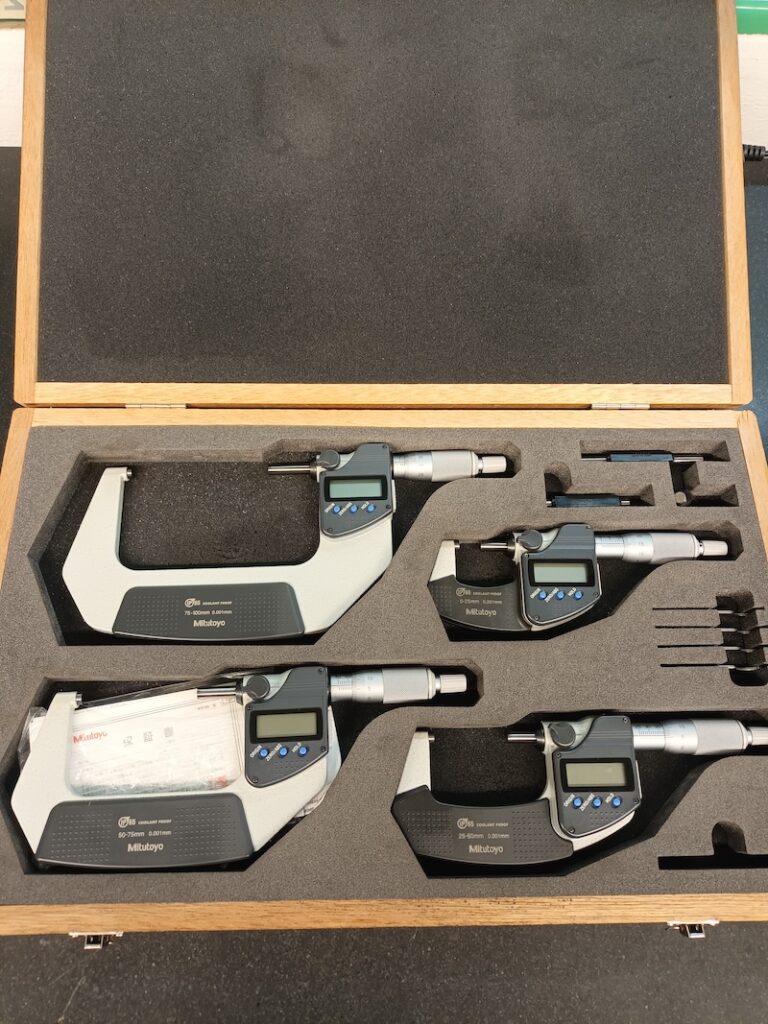

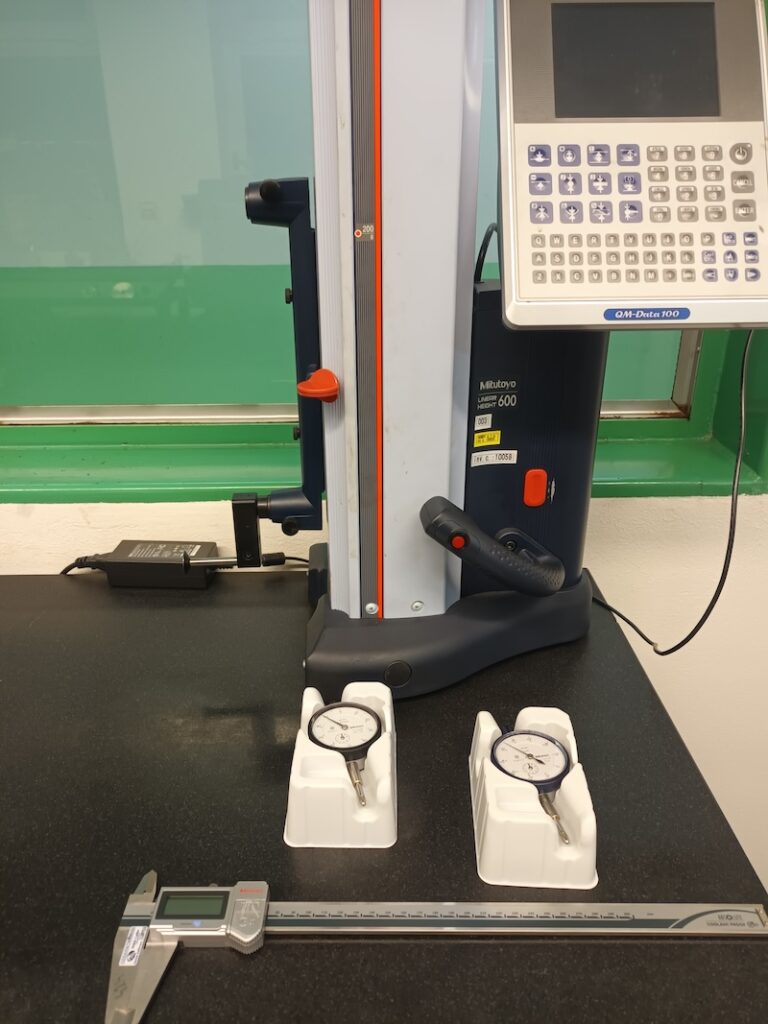

Our Klingelnberg measuring center has been refurbished by the Czech company Geartec, which added new guides, a rotary encoder, and modern software. This allows us to perform advanced evaluations such as tooth topography analysis and determination of unknown gear modules. Conventional gear measurements are supported by rotary inspection devices, microscopes for worm pitch measurement, devices for checking worm gear center distances, and much more.For manual measurements, we rely on proven Mitutoyo instruments. All gauges are regularly calibrated, with full traceability of calibration certificates available for the past 10 years—even for instruments that have been decommissioned.